Our Services

Quality

Professionalism

Personal Service

C.N.C MACHINING

We put an emphasis on quality – must be at the top of our list! That's why we offer our clients engraving and milling with the most advanced and efficient CNC method; we possess 200 machines, especially made for processing all kinds of metals including aluminum, stainless steel, bronze and many more. our facilities included 3, 4 and 5 axis. Thanks to the CNC milling technology, milling, turning, engraving, stamping, wiring and ignition can be done easily in order to produce the most accurate and prestigious equipment on the market for you. The dimensions vary from one millimeter to 600 millimeters! From the first meeting to the audit report, we accompany you step-by-step, to make you feel we have your back and to reach the exact product you are interested in. Our audit facilities include 2D, D3, etc. You will also receive a review report and warranty on the raw materials which are being used in the project, indicating their high quality, just like ours.

PLASTIC PARTS AND MOLDS

S.O.M offers design and manufacturing services for raw materials such as plastics or rubber, by injection molding. Thanks to our injection technology, you can manufacture and design the quality raw materials we acquire, so it'll shape to the exact product you need. With over 12 years of experience in the field, each design or production receive their own unique work flow, ensuring quality products and a simple, fast and smooth operation; we are proud of our manufacturing and organized conduct; the quality of our products is guaranteed, delivery is always on time and if that is not enough, we have a team of professional engineers to support your project. - So simple that it is inconceivable.

MIM

This incredible design technology by metal injections produces very complex parts from a wide range of raw materials, with very high endurance and quality surface finish. In addition, metal injections enable the application of heat treatment to metals, ensuring quality treatment and careful attention to the most technical details.

Manufacturing MIM parts, steel injections, up to finished product at high quality levels, for all materials, stainless steel up to 300 grams divided.

Ability to complete processing of dimensions in supplementary processing.

Over molding after manufacturing MIM parts.

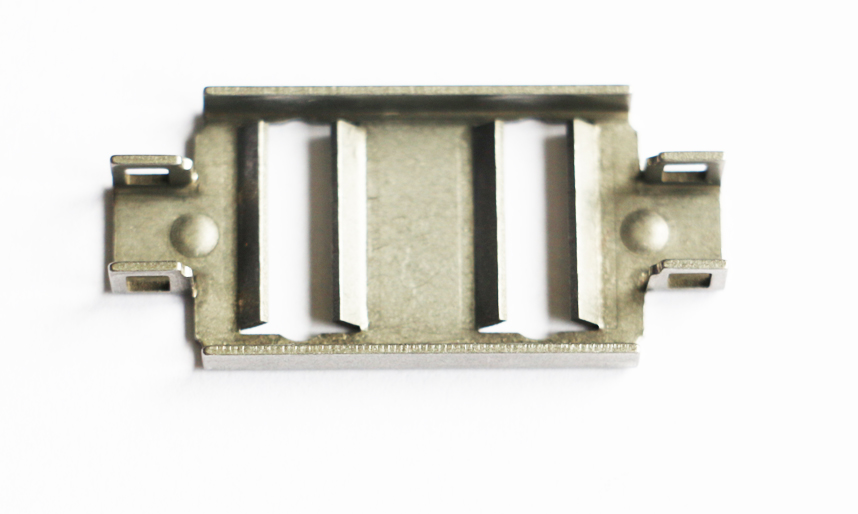

SHEET METAL STAMPING

In order to produce the best metal sheets for you, we have stamping, molding and pressing machines especially made for the job. The embedding machines provide the necessary strength, so that it is possible to add color, change and cut the metal sheets into perfect, precise and high quality parts according to your specific request.

JIGS AND FIXUTRE

When working with metals, many tools are necessary. Essential among them are measurement and installation tools by which you can control the movement and positioning of other tools, or hold specific tools at your desired location. The two tools are different in purpose: The jig is usually described as a plate or a box, used to hold work in place or to guide a tool in the desired direction. Its use concentrates mainly on locating drilling holes and creating a space between them. In contrast, the fixture is described as a set of instruments that allow the holding of work in machine tools, especially made for jobs which require working in a straight line or using a machine which works in straight lines, such as milling machines and professions. In addition, it helps to hold specific parts at desired positions in various processes such as assembly and welding

This department is used to manufacture JIGS AND FIXUTRE , including round grinding and precision micron assemblies

EVA PACKING

Today, packaging can be made from EVA pages, which are similar to cardboard, but are of much better quality due to their durability. The packaging will satisfy your exact requirements - whether it is color, size or anything that suits your spirit. We have huge quantities of molds in different sizes and patterns, to suit your diverse requirements. With robust technical support and infinite knowledge from our team, we have expanded the use of EVA to more solid, sealed and promising horizons